What’s it like to start a brewery? I have no idea, it’s only been a couple of weeks. Check back with me in a few months. I’ll be a grizzled old pro by then and I’ll be happy to give you a full report. What I can do is give you a visual tour of a typical week in the life of our fledgling startup brewery. Here goes…

A week in the life of a young Old Ox

In the mean time, we’ve been keeping very busy. We’ve gone over every inch of our new home with a fine toothed comb and found some pretty cool treasures along the way.

We’ve been going over design plans with the architect and engineers to make sure we’re ready to rock once we get the ole rubber stamp on the building permits. (Confession time: I don’t know what I’m doing in this picture. Not even sure that’s a ruler in my hand. May very well be a pixie stick or something.)

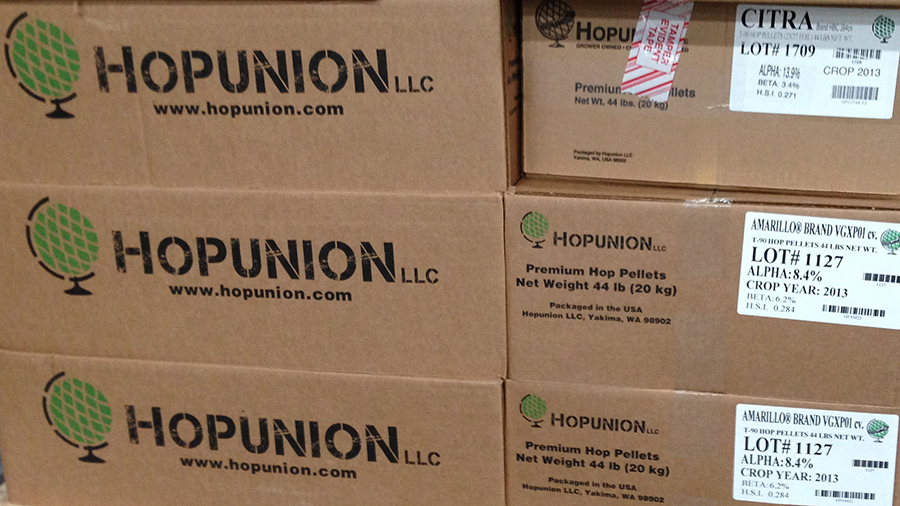

We’ve scored over 1200lbs of mind blowingly fantastic aroma hops. This was one of my big concerns going into our first year of business. (News flash, we’re in the middle of a global hop shortage. You may now commence panicking.) How the heck was I going to get my hands on the hops I needed when so many other breweries are scrambling for the same ones? Well, turns out we did pretty well for ourselves this month so I turned my attention to other worries like… where the deuce am I going to store 1200lbs of mind blowingly fantastic aroma hops?!?!

We’ve scored over 1200lbs of mind blowingly fantastic aroma hops. This was one of my big concerns going into our first year of business. (News flash, we’re in the middle of a global hop shortage. You may now commence panicking.) How the heck was I going to get my hands on the hops I needed when so many other breweries are scrambling for the same ones? Well, turns out we did pretty well for ourselves this month so I turned my attention to other worries like… where the deuce am I going to store 1200lbs of mind blowingly fantastic aroma hops?!?!

We came up with a solution for that thanks to a groovy couple out in Winchester who sold us a great little walk-in cooler. The cooler is eventually going to be the keg cooler for the tasting room but for now it’s keeping our hops at a chilly 40°F. We didn’t feel like setting up the compressor and evaporator for the walk-in just yet since we’re going to have to move it around during construction so we rigged a window a/c unit to provide cooling power. Pretty sure I voided the warranty here.

We came up with a solution for that thanks to a groovy couple out in Winchester who sold us a great little walk-in cooler. The cooler is eventually going to be the keg cooler for the tasting room but for now it’s keeping our hops at a chilly 40°F. We didn’t feel like setting up the compressor and evaporator for the walk-in just yet since we’re going to have to move it around during construction so we rigged a window a/c unit to provide cooling power. Pretty sure I voided the warranty here.

We’ve also done an impressive amount of sitting. Mostly sitting at our computers, in a cold warehouse, wearing flannel, not surfing porn. And by not surfing porn I mean working. Sourcing equipment, talking with potential suppliers/distributors, introducing ourselves to retailers, working on branding/marketing, setting up our business systems, finalizing licensing documentation, etc., etc.

When we aren’t sitting, we’re brewing. We’ve been brewing pilot batches at a rate of 2 per week. Pretty soon we’re going to be drowning in beer. Not a bad way to go, I’m told. Anyone have any ideas on how we can dispose of this stuff? It’s becoming a real nuisance.